Stock Code: 300837

+86-21-50903001

ormaise@cnzkzg.com

International Sales Center

Tel:+86-21-50903001

+86 13585569799

E-mail:ormaise@cnzkzg.com

Add:Room 609, Block B, No. 308 Lanhua Road,Pudong New Area,Shanghai,China

Corporate Headquarters

Tel:+86-572-6955888

E-mail:zkzg@cnzkzg.com

Add:Heping Industrial Park, Changxing County, Zhejiang Province,China

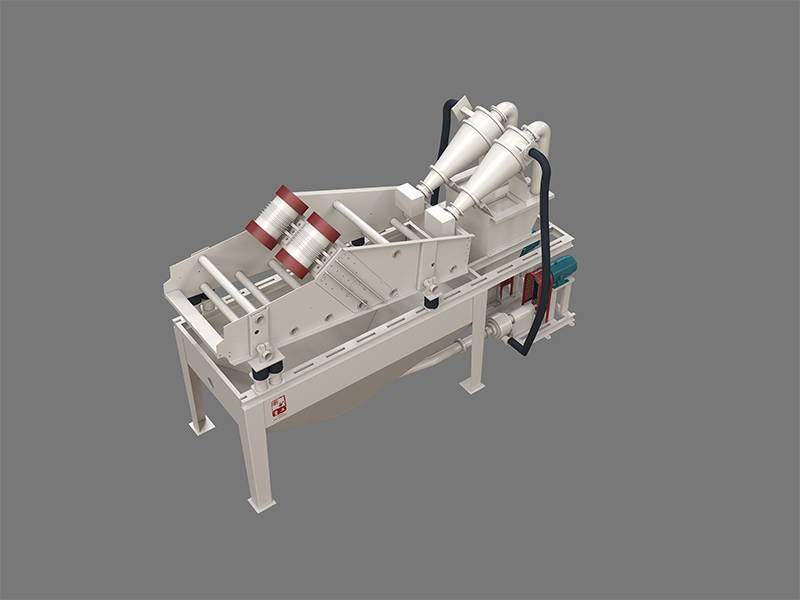

The WS Series Fine Sand Recovery Device developed by our company can solve the problems of large loss of fine sand (particles below 0.16MM) and unreasonable sand gradation in the existing artificial sand production line. This system is a world-advanced fine material recovery device designed by absorbing foreign advanced technology and combining with the actual situation of our country. It can improve the product quality of machine-made sand, reduce fine sand discharge, and reduce environmental pollution. Therefore, it is widely used in sand and gravel aggregate processing systems of hydropower stations, glass raw material processing systems, artificial sand production lines, recovery of coarse coal slime in coal preparation plants and environmental protection projects (mud purification, etc.), and can effectively solve the problem of fine sand recovery.

The slurry pump transports the sand-water mixture to the cyclone, and the fine sand concentrated by centrifugal classification is supplied to the vibrating screen through the grit settling nozzle. After being dehydrated by the vibrating screen, the fine sand and water are effectively separated, and a small amount of fine sand and mud are returned to the cleaning tank through the return box. When the liquid level in the cleaning tank is too high, it is discharged through the discharge port. The weight concentration of the recovered material from the linear vibrating screen is 70%-85%. Adjusting the fineness modulus can be realized by changing the pump speed, changing the mortar concentration, adjusting the overflow water volume, replacing the sand nozzle, and finally completing the three functions of cleaning, dehydration and grading.

1. The vibrating screen adopts polyurethane screen, which has a longer service life than other types of screens, and the holes are not easy to be blocked;

2. The cyclone is lined with polyurethane to prolong the service life of the whole device, and can successfully complete the work of slurry concentration and liquid clarification;

3. The maximum recyclable fine particle material volume of the fine sand recovery system accounts for 85% of the total discharge, which has unparalleled technical and economic advantages compared to other equipment;

4. Fine particles can be fully recovered, reducing the workload and cleaning costs of the sedimentation tank.