Stock Code: 300837

+86-21-50903001

ormaise@cnzkzg.com

International Sales Center

Tel:+86-21-50903001

+86 13585569799

E-mail:ormaise@cnzkzg.com

Add:Room 609, Block B, No. 308 Lanhua Road,Pudong New Area,Shanghai,China

Corporate Headquarters

Tel:+86-572-6955888

E-mail:zkzg@cnzkzg.com

Add:Heping Industrial Park, Changxing County, Zhejiang Province,China

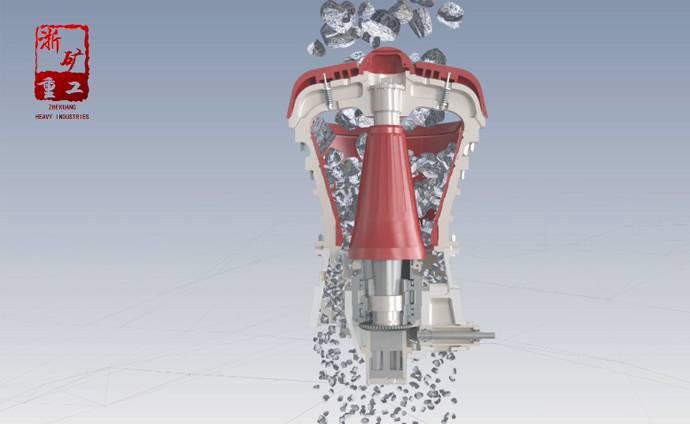

Gyratory crusher is suitable for the primary crushing of various rocks and ores. Compared with other primary crushing equipment, it has the characteristics of large processing capacity, high crushing efficiency, large crushing ratio, uniform product size, low energy consumption, uniform wear in the crushing chamber, etc., and is suitable for use under the conditions of large-scale production.

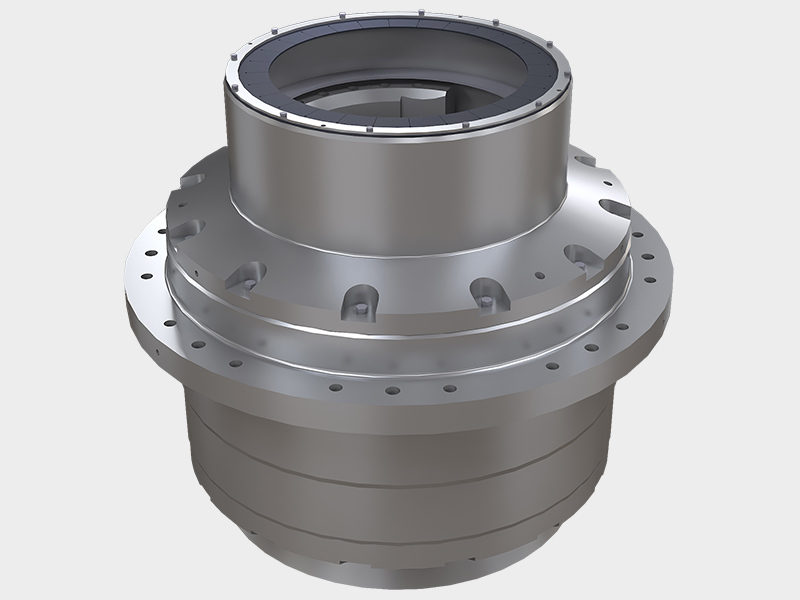

Gyratory crusher is suitable for the primary crushing motion of the crushing cone in the cone cavity in the frame to squeeze, split and bend materials, and roughly crush ores or rocks of various hardness. Its main shaft is located on the piston in the hydraulic cylinder. Changing the volume of hydraulic oil under the piston can change the upper and lower positions of the crushing cone, thereby changing the size of the discharge port. When overloaded, the downward pressure on the main shaft increases, forcing the hydraulic oil under the piston into the accumulator in the hydraulic transmission system. The crushing cone is then lowered to enlarge the discharge port, and the non-broken objects (metal, wood blocks, etc.) that enter the crushing cavity with the material are discharged.

1. The crushing cavity with a large inclination angle and the long crushing surface can realize continuous crushing, thereby improving efficiency and increasing output;

2. The liner made of special materials gives the crusher a strong crushing capacity and prolongs the life of the liner. The heavy-duty frame, the main shaft and the moving cone adopt an integrated structure design to avoid the loosening of the moving cone during the crushing process, ensuring a longer service life and a safer and more reliable operating state;

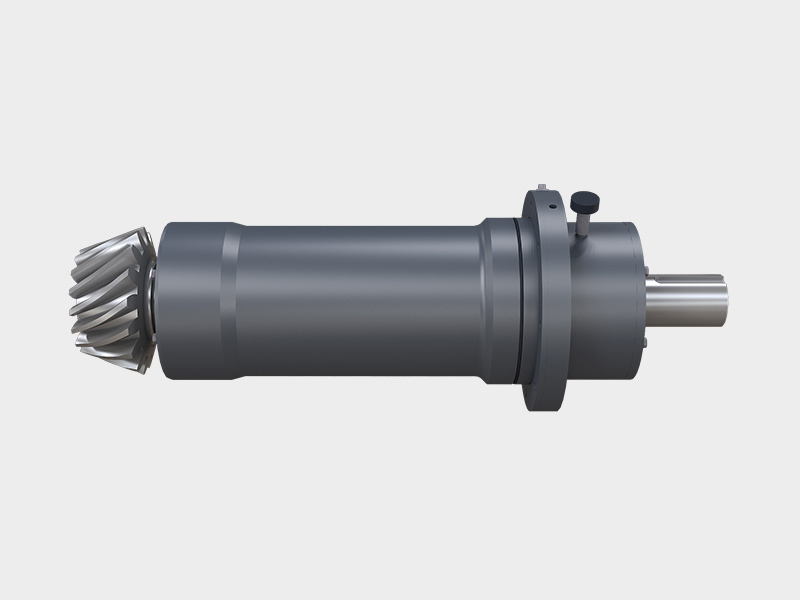

3. Spiral bevel gear transmission, high load capacity, stable operation and low noise;

4. Automatically detect the size of the discharge port, and cooperate with the hydraulic system to realize automatic adjustment to ensure the stability of the discharge particle size;

5. Over-iron protection function, the piston accumulator and the one-way valve make the main shaft drop quickly and rise slowly when the crushing chamber enters superhard objects, discharge the superhard objects, reduce the impact, and ensure safe and stable operation;

6. Effective dust-proof sealing, the assembled positive pressure blower ensures that no dust enters the eccentric device;

7. Real-time monitoring of the oil level, oil temperature, oil pressure, flow rate, and position of the moving cone in key parts of the hydraulic and lubrication system, so as to realize a rapid diagnosis and timely repair of faults, and greatly shorten the downtime of faults. Real-time monitoring of transmission shaft bearing temperature, timely detection of abnormal conditions, timely maintenance, and prolonging the service life of bearings. Monitor the material level of the lower silo in real time to prevent the silo from being blocked and ensure the safe operation of the main engine. The Internet function realizes the remote real-time monitoring of the operating status of the equipment, and the historical data can be used for automatic analysis and process optimization.