Stock Code: 300837

+86-21-50903001

ormaise@cnzkzg.com

International Sales Center

Tel:+86-21-50903001

+86 13585569799

E-mail:ormaise@cnzkzg.com

Add:Room 609, Block B, No. 308 Lanhua Road,Pudong New Area,Shanghai,China

Corporate Headquarters

Tel:+86-572-6955888

E-mail:zkzg@cnzkzg.com

Add:Heping Industrial Park, Changxing County, Zhejiang Province,China

RC Series Cone Crushers are optimized and designed on the basis of absorbing the world's advanced crushing technology, and are widely used in secondary, tertiary or quaternary crushing in mines.

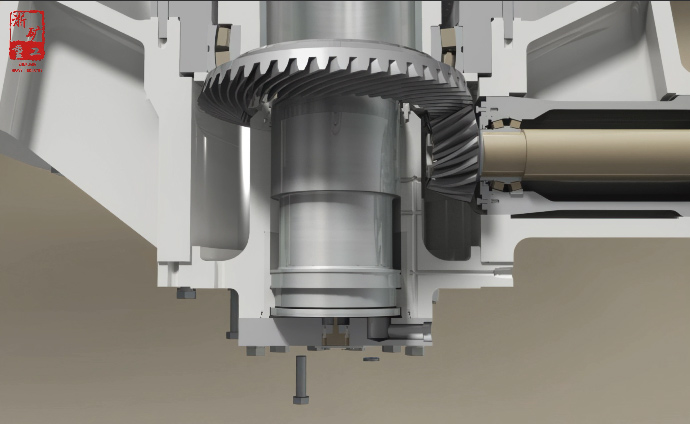

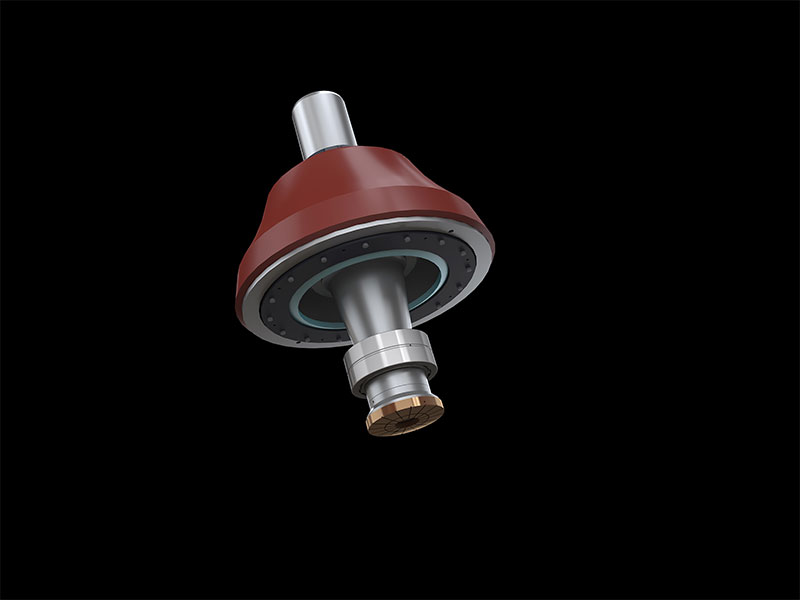

During the operation of the RC series single-cylinder hydraulic cone crusher, the motor drives the eccentric sleeve to rotate through the transmission device, and the moving cone rotates and swings under the force of the eccentric shaft sleeve. The section of the movable cone close to the fixed cone becomes the crushing cavity, and the material is crushed by the multiple extrusion and impact of the movable cone and the fixed cone. When the moving cone leaves this section, the material that has been broken to the required particle size falls under its own gravity and is discharged from the bottom of the cone. The size of the discharge port is adjusted by the lifting of the hydraulic cylinder at the bottom.

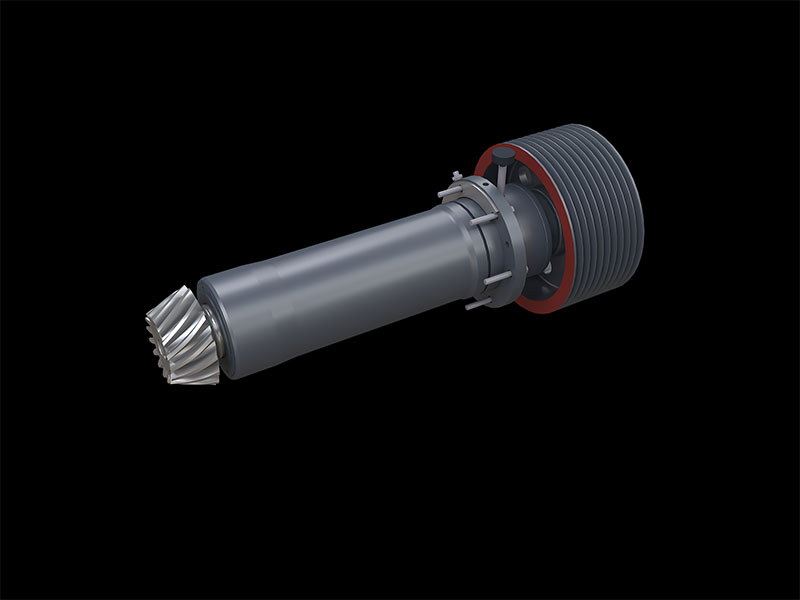

1.The whole machine adopts CAD optimization design, equipped with a large-diameter high-strength main shaft and a heavy-duty main frame, which makes the equipment more durable;

2.Heavy-duty rolling bearings are used to replace the copper sleeves of traditional models, reducing the fit clearance, increasing the swing speed of the main shaft, increasing the output, and optimizing the grain shape;

3.The hydraulic control system facilitates the adjustment of the discharge port and provides more reliable overload protection;

4.The stroke can be changed according to the nature of the material, so as to adapt to different crushing needs;

5.The advanced automatic control system can maintain maximum crushing efficiency within a safe range while improving product quality;

6.The principle of "laminated crushing" is applied and the optional speed, steep angle and hyperbolic crushing cavity shape are used to ensure perfect and consistent product grain shape;

7.Each model has a variety of crushing chambers to choose from to meet the diverse needs of customers;

8.The upper frame is divided into two parts, the arm frame and the broken wall bearing seat, which can be repaired independently in case of damage to reduce costs;

9.The spiral bevel gear transmission is adopted to increase the bearing capacity and make the operation more stable;

10.The structure of the whole machine is simple and easy to operate, which greatly reduces the maintenance time of workers and improves production efficiency.

Note: The above data is based on the loose bulk density of 1.6t/m³, and the feeding material that can enter the crushing chamber smoothly. Due to different factors such as material type, feed material gradation, moisture content, installed liner type and its material type will affect the production capacity of the crusher, the actual production results will be different from the table. To choose a crusher suitable for your specific conditions, please consult Zhekuang Heavy Industry.