Stock Code: 300837

+86-21-50903001

ormaise@cnzkzg.com

International Sales Center

Tel:+86-21-50903001

+86 13585569799

E-mail:ormaise@cnzkzg.com

Add:Room 609, Block B, No. 308 Lanhua Road,Pudong New Area,Shanghai,China

Corporate Headquarters

Tel:+86-572-6955888

E-mail:zkzg@cnzkzg.com

Add:Heping Industrial Park, Changxing County, Zhejiang Province,China

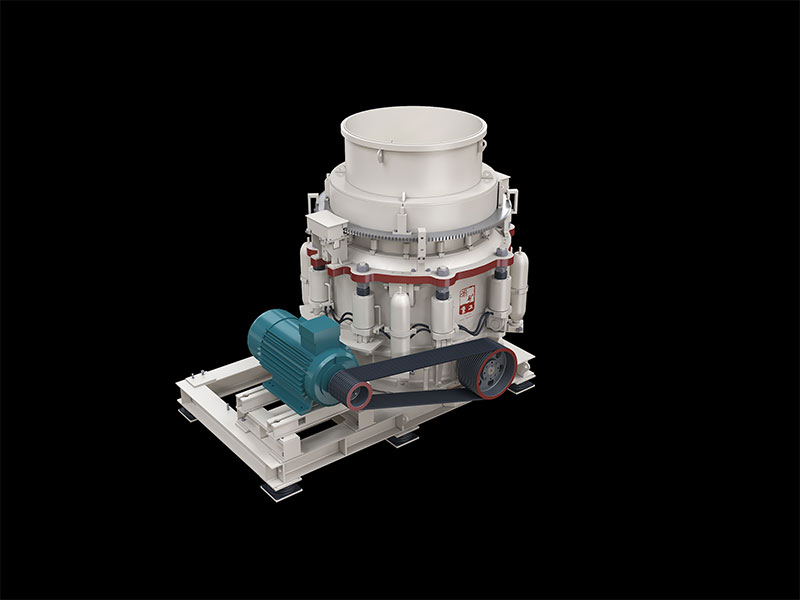

Through the advanced design, the cavity shape of the MRC series multi-cylinder hydraulic rolling bearing cone crusher is optimized, which makes the gradation of the produced stone better and increases the throughput. This series of products is suitable for various fields such as metal and non-metal mines, building materials, and chemical raw materials.

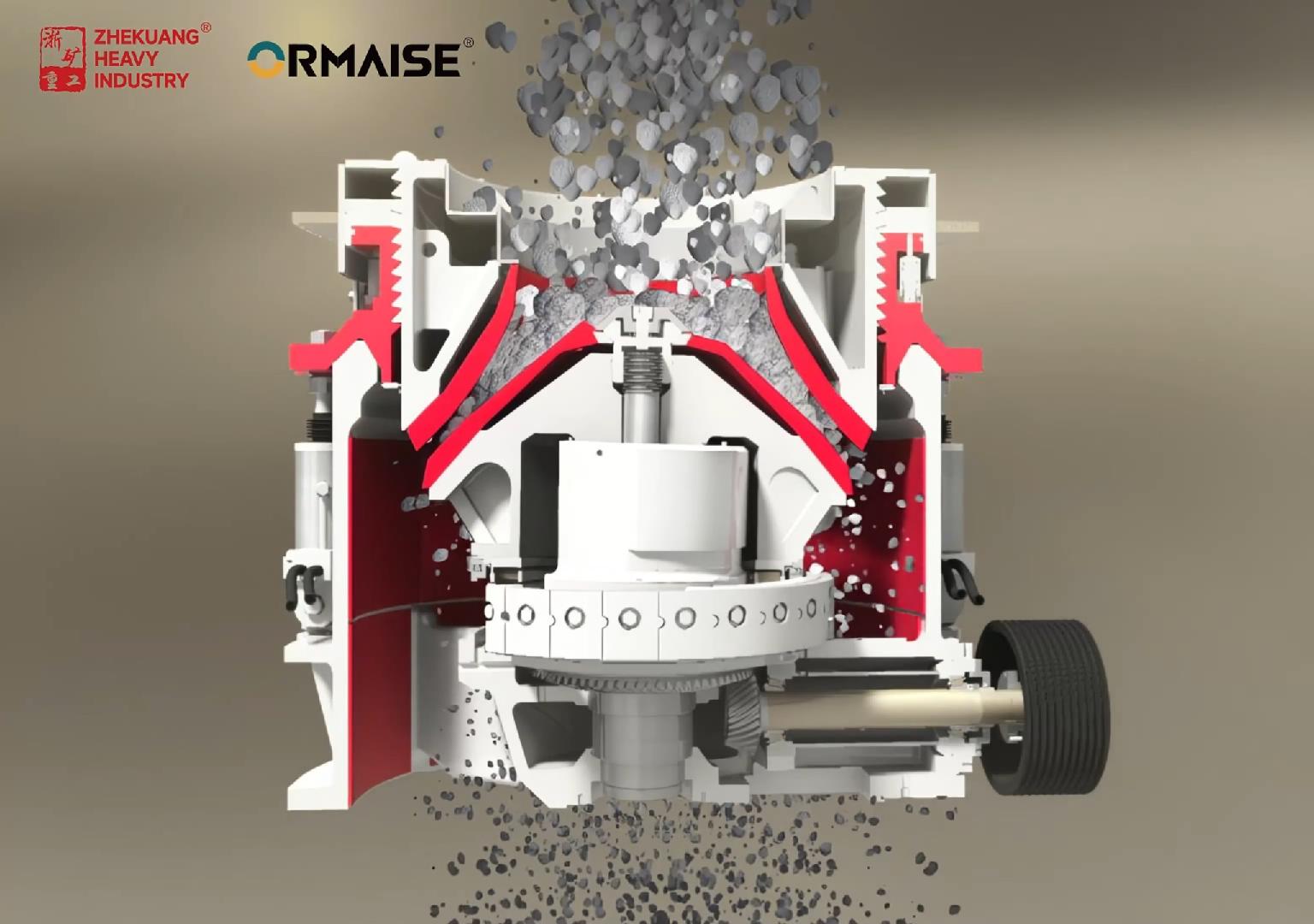

During the operation of the MRC series multi-cylinder hydraulic cone crusher, the moving cone performs a swinging motion along the inner surface. The material close to the fixed cone is crushed by the extrusion and bending of the moving cone; the broken material falls from the bottom of the cone due to gravity at the place away from the moving cone. The whole crushing and unloading process is carried out continuously and sequentially along the inner surface. The locking protection oil cylinder is composed of several locking protection oil cylinders, iron protection accumulators, buffer accumulator groups and pipelines, and mainly plays the role of iron protection and cleaning of the crushing cavity. Every two hydraulic cylinders are equipped with a buffer accumulator, which is used to absorb the jumping impact of the adjustment ring caused by a small number of hard materials during buffering during normal crushing.

1.The advanced crushing chamber design increases the content of cubic products; the longer crushing chamber and greater holding force increase the throughput; multiple speeds and chamber types can produce more corresponding types of products and reduce energy consumption;

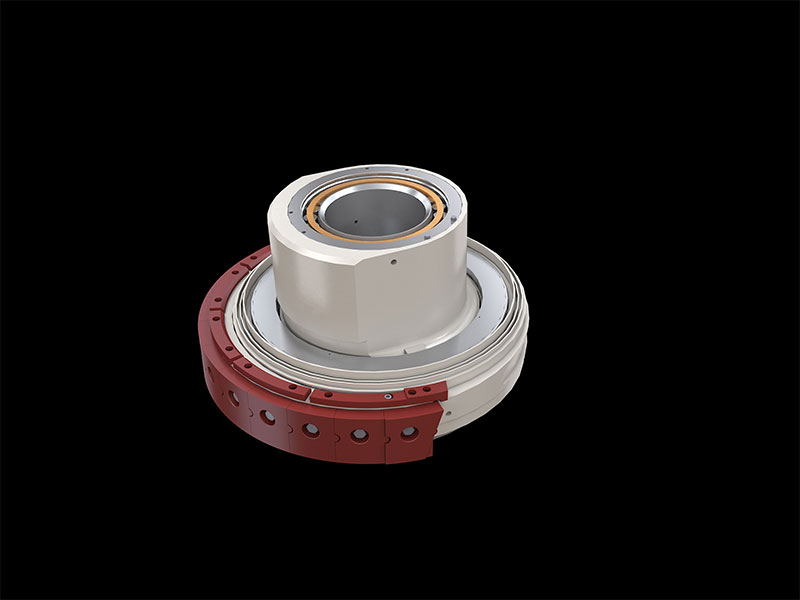

2.The full rolling bearing design can convert more horsepower into crushing force, reduce friction and heat, increase output per unit time, and prolong bearing service life;

3.The large-diameter thrust bearing can increase the bearing capacity, and is more suitable for metal mines with hard ore;

4.Heavy-duty cast steel frame can withstand harsh working conditions and prolong service life;

5.The hydraulic control system facilitates the adjustment of the discharge port and provides more reliable overload protection;

6.The advanced automatic control system is easy to operate and stabilizes the operation of the machine;

7.The backstop can prevent the moving cone from rotating during no-load operation, reducing additional wear;

8.The simple operation of switching between coarse crushing and fine crushing can be realized by replacing the liner to meet different crushing requirements.

Note: The above data is based on the loose bulk density of 1.6t/m³, and the feeding material that can enter the crushing chamber smoothly. Due to different factors such as material type, feed material gradation, moisture content, installed liner type and its material type will affect the production capacity of the crusher, the actual production results will be different from the table. To choose a crusher suitable for your specific conditions, please consult Zhekuang Heavy Industry.