Stock Code: 300837

+86-21-50903001

ormaise@cnzkzg.com

International Sales Center

Tel:+86-21-50903001

+86 13585569799

E-mail:ormaise@cnzkzg.com

Add:Room 609, Block B, No. 308 Lanhua Road,Pudong New Area,Shanghai,China

Corporate Headquarters

Tel:+86-572-6955888

E-mail:zkzg@cnzkzg.com

Add:Heping Industrial Park, Changxing County, Zhejiang Province,China

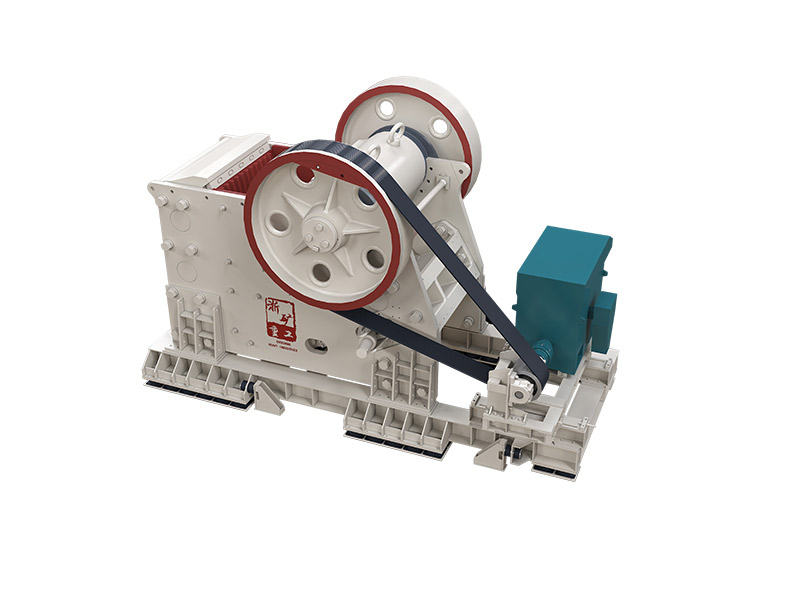

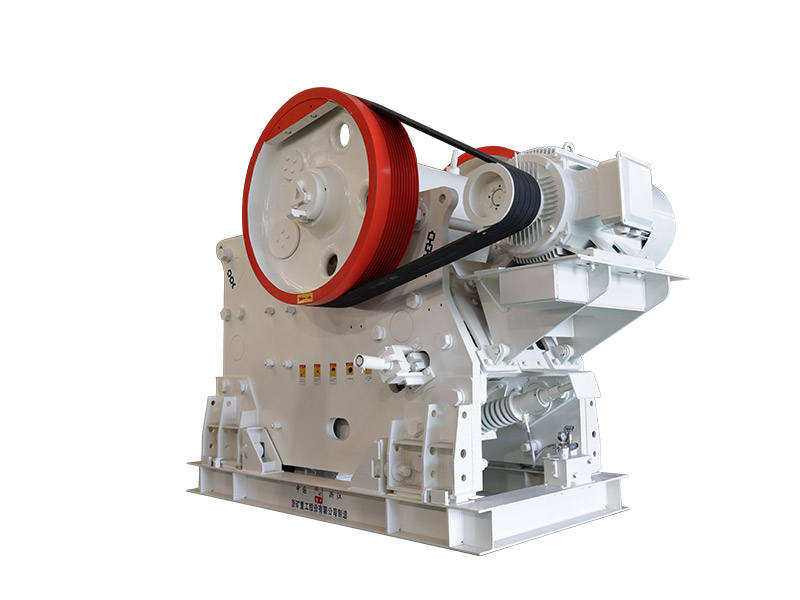

CJ Jaw Crusher series is widely used in the primary crushing of various mines, and can crush various stones with a hardness not greater than 320MPa.

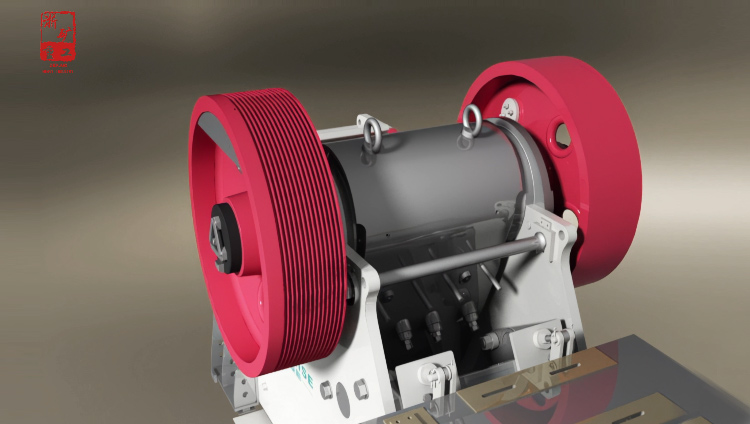

The CJ Series Jaw Crusher adopts the working mode of the crank extrusion type. The motor drives the pulley to drive, and the movable jaw moves back and forth and up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw to approach the fixed jaw, and at the same time, the material is crushed or chopped to achieve the purpose of crushing; when the movable jaw moves down, the angle between the toggle plate and the movable jaw becomes smaller, and the movable jaw leaves the fixed jaw under the action of the pull rod and the spring, and the crushed materials are discharged from the lower opening of the crushing chamber. With the continuous rotation of the electric motor, the movable jaw of the crusher will do periodic motion to crush and discharge the materials to realize mass production.

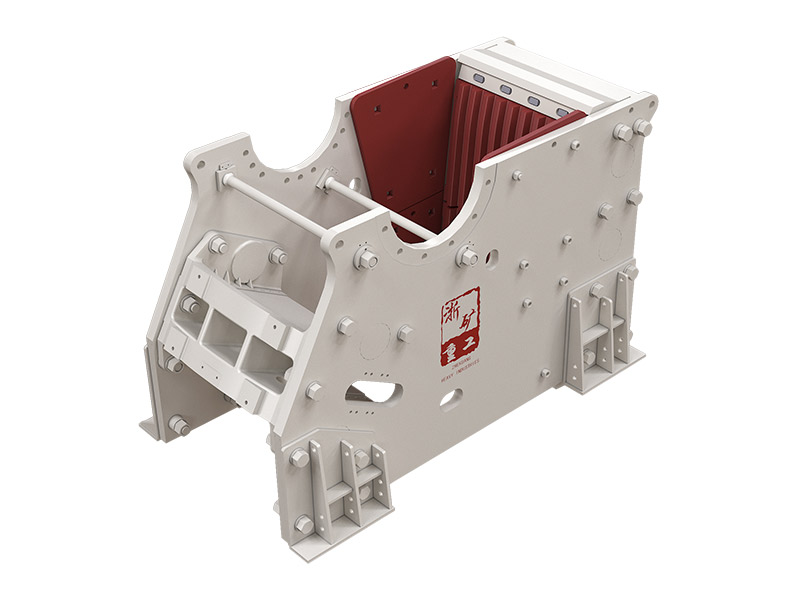

1. Modular design and non-welding structure make the structure light and strong, and the impact resistance is stronger;

2. High-quality bearings with large specifications, longer product life, and more guaranteed quality;

3. The eccentric shaft is made of heavy-duty forged alloy steel, and the front and rear frames are made of high-strength cast steel;

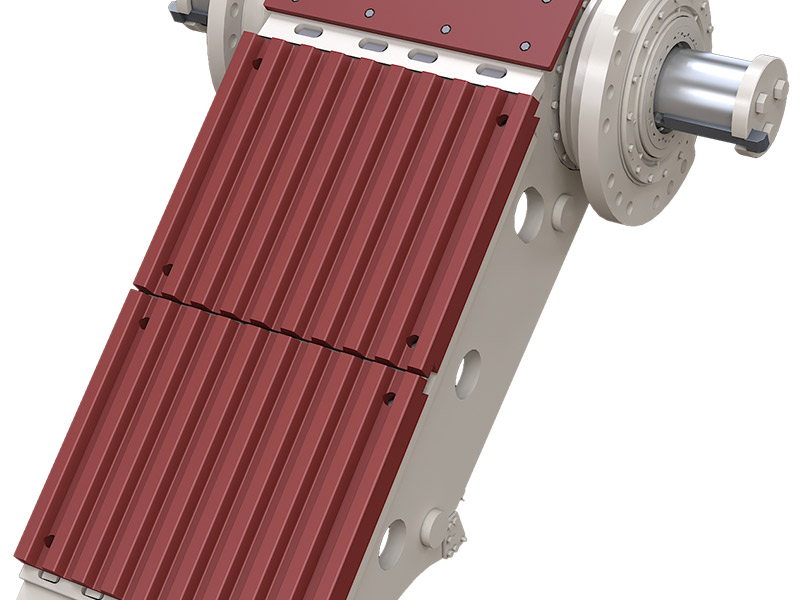

4. The optimized crushing mechanism optimizes the nip angle and stroke and improves the crushing ratio;

5. The higher speed increases the throughput and the times of material crushing, thus greatly increasing the production capacity;

6. Realize quick adjustment of the discharge opening, both hydraulic and mechanical can be adjusted by wedges from both sides;

7. Easy maintenance and installation, low operating cost;

8. Widely applicable and can be used in various mobile crushing stations.

Technical Parameter:

Note: The above data is based on the loose bulk density of 1.6t/m³, and the feeding material that can enter the crushing chamber smoothly. The processing capacity in the table is the instantaneous maximum processing capacity, and changes according to the material properties, feeding method, water content, mud content, and other physical properties of the material. The discharge opening is defined as the distance from the bottom of the tip of the tooth to the top of the tip of the other jaw.